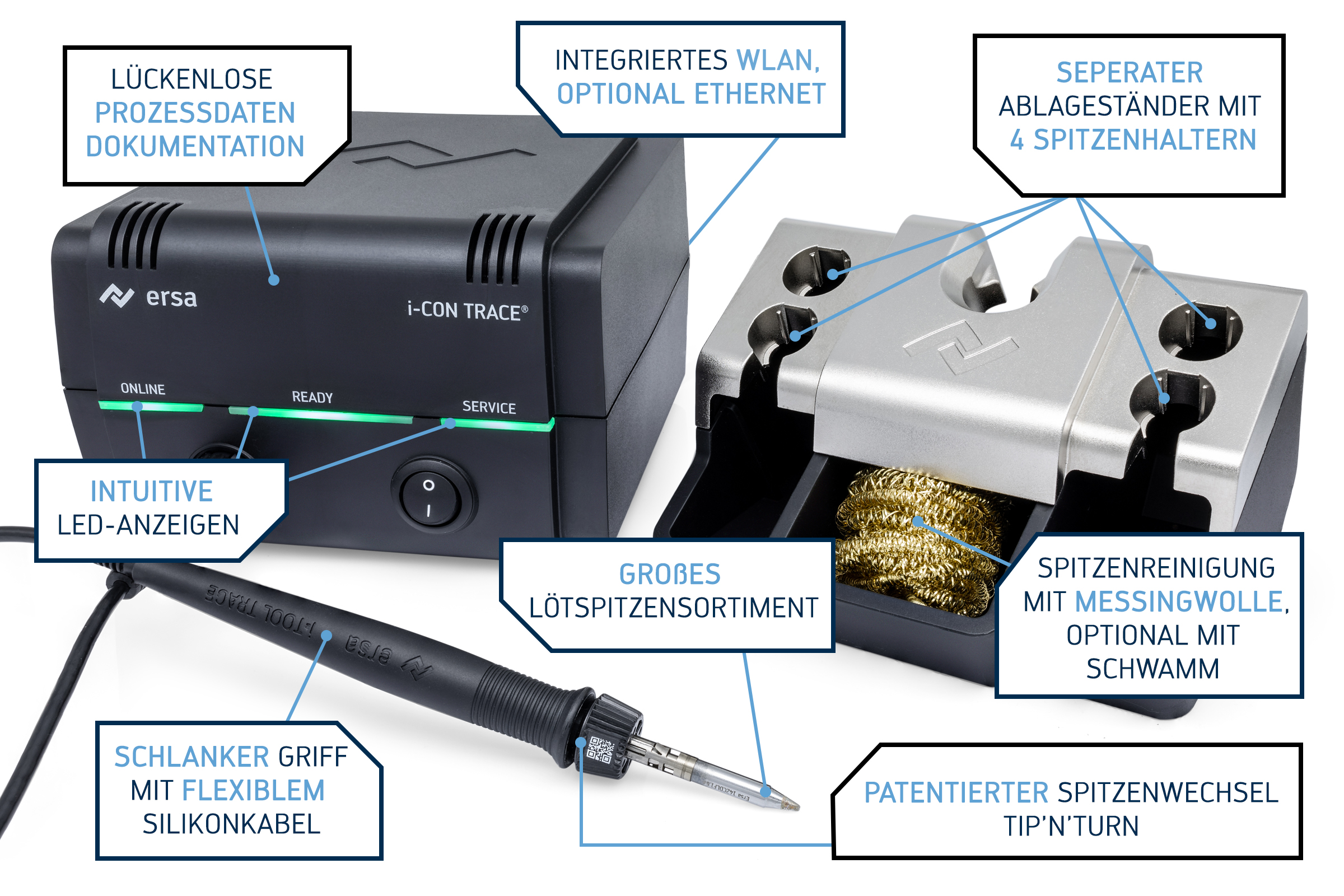

ERSA i-CON Trace IoT soldering station, 150W, connectable, virtually controllable

– ESD capable

– Temperature range: 50 – 450°C

– pre-assembled soldering tip chisel-shaped 1.6 mm

– Bluetooth 4.0 low energy.

– WLAN 2.4 GHz

– Ethernet capable with optional LAN card

Scope of delivery:

i-CON Trace base station 0ICT103A

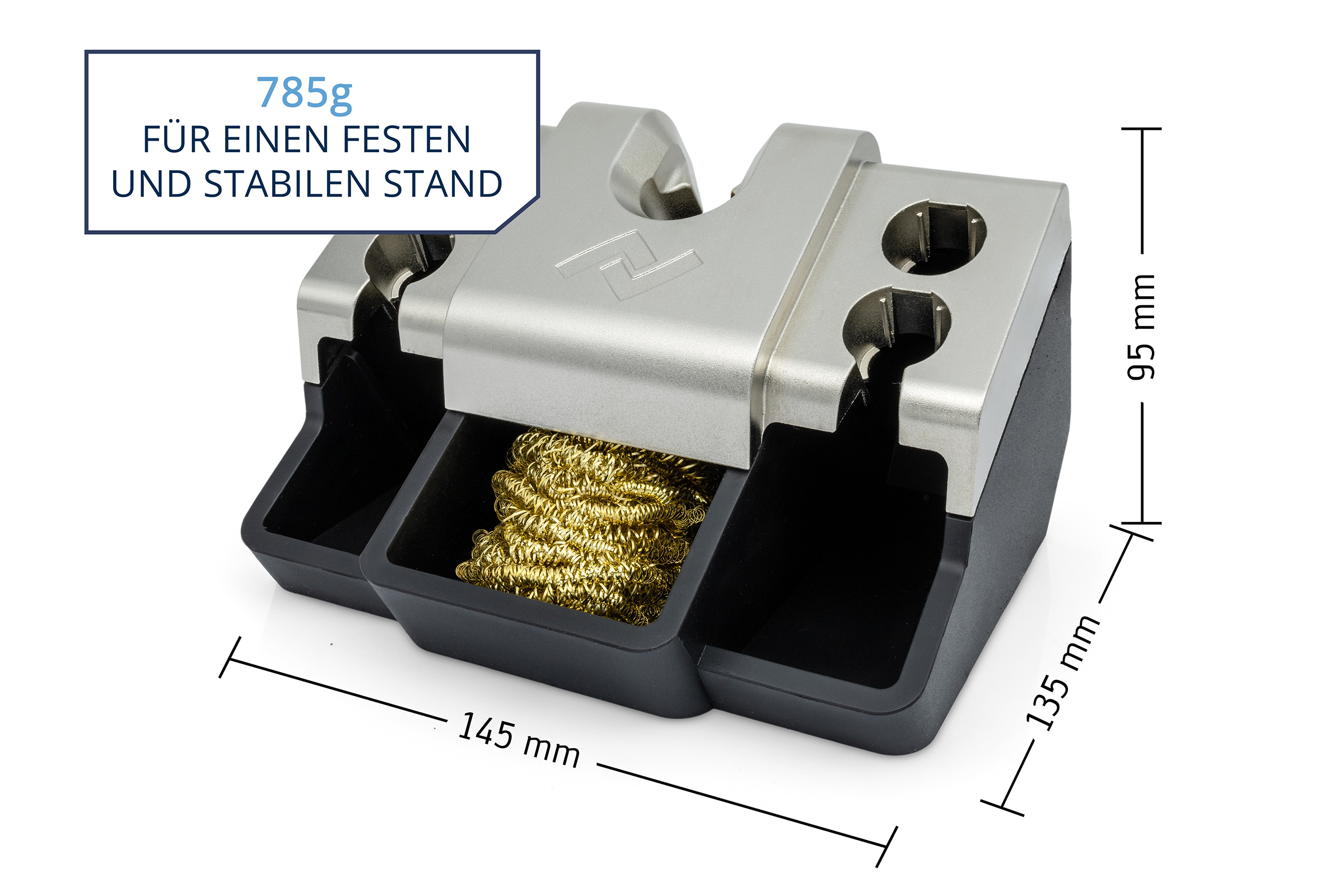

0A58 soldering iron holder

150W soldering iron 0140CDJ, incl. soldering tip 0142CDLF16

The Ersa IoT i-CON TRACE soldering station is designed primarily for use in a digitally networked environment – essential settings are made via input devices that are already integrated into the company network (PC, tablet, smartphone) or via an MES. This enables the user to access all soldering stations in the network at the same time and makes operation extremely convenient. It also ensures detailed process control in hand soldering.

Further highlights:

Seamless traceability and documentation of the hand soldering process

High process reliability through the presetting of all parameters and process data documentation

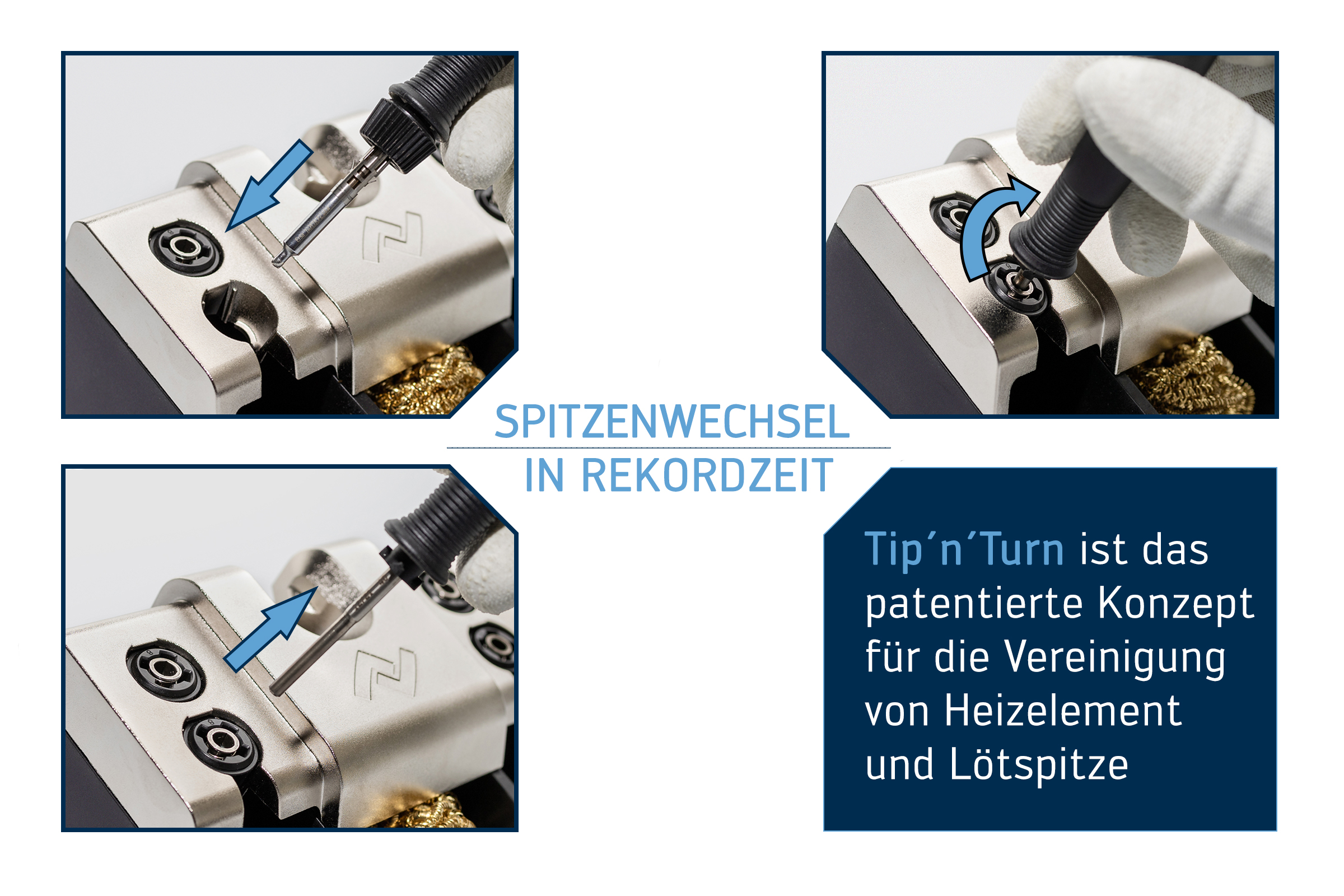

Increased productivity and soldering quality through Tip’n’Turn soldering tip changing

– Highest precision and excellent reliability

– Significant cost savings through separately replaceable soldering tips

As the first IoT soldering station from Ersa, the i-CON TRACE is revolutionizing the market for industrial soldering stations. The i-CON TRACE is the first soldering station that enables seamless process control for hand soldering even in its delivery state.

The soldering station is primarily intended for use in a digitally networked environment – essential settings are made via input devices in the network, such as PCs, tablets or smartphones. Of course, an MES (Manufacturing Execution System) can also be used for data exchange. This enables the user to access all soldering stations in the network simultaneously and makes operation extremely convenient.

Minimum requirements of the APP/software:

– iOS10.0

– Android 8.0

– Windows 10

– Windows Server 2016